Tailings dam management encompasses a set of technical, environmental and safety practices and procedures designed to manage structures that store materials generated by mining industrial processes. This approach aims to minimize risks, ensure the safety of the structures and nearby communities, and mitigate social and environmental impacts.

See below for further details on the topic:

OBJECTIVES

- Prevent accidents and disasters.

- Reduce risks to public health.

- Minimize environmental impacts.

- Ensure the stability and safety of structures.

- Comply with regulations and technical standards.

- Promote environmental responsibility.

KEY COMPONENTS

- Design and construction: safe planning, engineering and construction.

- Monitoring: continuous oversight of parameters such as structural stability.

- Maintenance: regular repairs and updates.

- Safety: emergency plans, team training and communication with communities.

- Environment: assessment and mitigation of environmental impacts.

- Communication: transparency with stakeholders and communities.

- Legislation and regulation: compliance with applicable standards and regulations.

IMPLEMENTED PRACTICES

- Periodic risk assessments.

- Regular inspections.

- Stability analyses.

- Monitoring.

- Closure planning.

- Team training and capacity building.

- Independent audits.

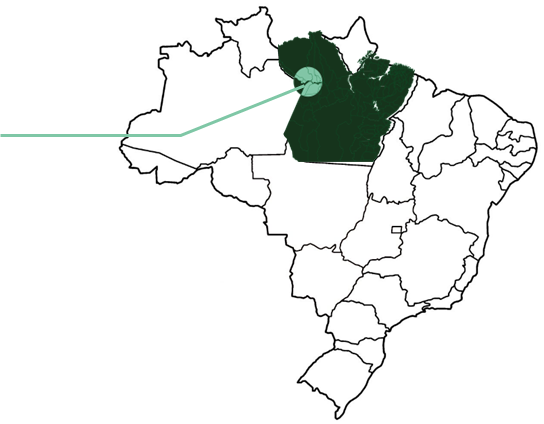

Location of MRN dam structures

|

|

Understanding the Topic in Greater Detail

Tailings containment dams are structures designed to safely store the tailings generated during the mineral processing stage. At MRN, safety is the fundamental principle guiding the entire disposal system.

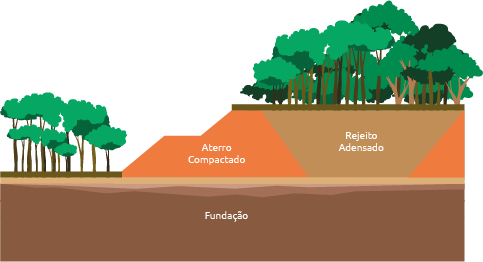

How are they built?

MRN’s dams are designed based on rigorous engineering criteria aimed at preventing any risk of leakage or failure. All structures are built in a single construction phase, in accordance with global engineering best practices.

In addition, the structures do not rely on natural topography, such as valleys, to contain tailings. Instead, they are artificially constructed on flat terrain, providing greater stability, control and safety.

What are MRN’s tailings?

The tailings generated by MRN consist exclusively of water and clay, with no chemical additives. Classified under ABNT standards as Class II B – non-hazardous waste, they are:

• Non-toxic

• Non-flammable

• Non-corrosive

• Non-radioactive

Adaptation to the Amazon Climate

As it operates in a region with intense rainfall, MRN adopts measures that minimize the influence of rain on its structures. Because the dams are isolated from the natural landscape, rainwater affects only the built areas, which facilitates monitoring and technical control.

Do you know the difference between dams and reservoirs?

| What is the difference between dams and reservoirs? | What happens to tailings reservoirs after they are no longer in use? |  |

|

|

MRN’s reservoirs are located on top of a plateau and receive only the rainwater that falls within that specific area. This differs from dams located in valleys, which collect rainfall from all watercourses within the contributing watershed. |

At the end of their service life, tailings reservoirs receive a layer of treated soil, where native Amazon species are planted. Reforestation is also carried out in mined areas. |

Safety and Prevention: MRN’s Ongoing Commitment

MRN adopts rigorous engineering and operational standards to ensure the safety of its tailings structures. As part of this commitment, the company maintains a robust Emergency Action Plan for Mining Dams (PAEBM) and operates a control room equipped with state-of-the-art technology for real-time monitoring of its structures.

These initiatives are part of a continuous risk prevention and community protection strategy, reinforcing transparency, preparedness, and care for life and the environment.

Emergency Action Plan for Dams (PAEBM)

The PAEBM is a mandatory document for mining dams, established under Brazilian Law No. 12,334/2010, which sets forth safety guidelines to prevent and mitigate risks in the event of structural failures. It defines the measures and procedures to be adopted in emergency situations.

The primary objective of the PAEBM is to keep nearby communities, service providers and other stakeholders informed and prepared, promoting preventive actions and expanding awareness of the topic, with a focus on avoiding harm and preserving lives.

Real-Time Monitoring

MRN operates a dedicated control and monitoring room equipped with state-of-the-art technology to track, in real time, the performance of its tailings structures. Sensors, piezometers and automated systems enable the precise detection of variations and ensure a swift response to any anomaly.

This continuous monitoring strengthens the effectiveness of the PAEBM, enabling the immediate activation of emergency protocols whenever necessary.

Photo: Preparation for the simulation Photo: Orientation seminar in the community Photo: Civil Defense participation in the orientation seminar

Community Engagement Action Schedule

MRN develops an ongoing schedule of actions in partnership with Civil Defense authorities, municipalities and local leaders, with the aim of expanding access to information and strengthening a culture of prevention. Activities carried out include:

• Community visits to tailings structures

• Educational seminars and meetings

• Semiannual emergency drills

• Distribution of informational booklets and flyers

• Emergency siren testing

• Simulation exercises of the PAEBM notification flow

Global Industry Standard for Tailings Management (GISTM)

|

Since 2022, MRN has been dedicated to implementing the Global Industry Standard on Tailings Management (GISTM), developed to enhance safety, governance and transparency in the management of tailings disposal structures. This journey reflects our commitment to operational excellence, sustainability and social responsibility. In August 2025, MRN completed the implementation of the GISTM across all its tailings structures, fully meeting the deadline established by the International Council on Mining and Metals (ICMM) for structures classified as having low potential consequences. Throughout this process, we achieved significant advances in the definition of guidelines, the structuring of a robust knowledge base, the execution of risk assessments across the entire life cycle of the structures, from design to post-closure, and the engagement of different areas of the company and specialized technical partners. With the implementation completed, MRN will continue to promote the ongoing maintenance of the GISTM, ensuring continuous process updates, the consolidation of practices in daily operations, and the permanent strengthening of a culture of safety and prevention. We remain committed to contributing to a mining industry that is increasingly safe, transparent and aligned with the highest international standards. |

|

Commitment to Society

MRN assumed and fulfilled its public commitment to complete the full implementation of the GISTM by August 2025, aligning its operations with the highest technical, ethical and regulatory standards in the mining sector, in accordance with its shareholders’ guidelines.

This journey is supported by a robust Tailings Management System (TMS), which integrates corporate policies, structured processes, continuous training, independent audits and transparency mechanisms.

Governance and Accountability

MRN adopts a robust governance structure for tailings management, grounded in the principles of the GISTM and integrated into its Tailings Management System (TMS). This structure ensures that all processes are conducted with transparency, accountability and alignment with international best practices.

The governance framework includes formally designated roles that ensure technical oversight, strategic decision-making and continuous improvement:

- Accountable Executive (AE): strategic decision-making and institutional support;

- Engineer of Record (EoR): ongoing technical oversight of structural safety;

- Responsible Technical Engineer (RTER): technical and operational compliance;

- Independent Senior Technical Reviewer: critical and impartial review of adopted practices.

Dam Safety Management Policy

MRN has established its Dam and Geotechnical Structures Safety Management Policy, which guides the company’s actions with a focus on risk prevention and the protection of life, communities and the environment.

The policy sets out clear guidelines to ensure the integrity of tailings structures throughout all phases of their life cycle, aligned with international best practices and the principles of the GISTM, ICMM, ASI, IFC and the Equator Principles. Integrated into MRN’s Tailings Management System (TMS), it reinforces the company’s commitment to operational safety, sustainability and public trust.

Public Disclosure – Requirement 15.1

In compliance with Requirement 15.1 of the Global Industry Standard on Tailings Management (GISTM), MRN ensures the public, transparent and accessible disclosure of relevant information regarding its tailings disposal structures.

This disclosure aims to:

• Strengthen stakeholder trust through transparency;

• Ensure public access to technical, operational, environmental and social data related to the structures;

• Demonstrate responsible risk management and performance of tailings dams and reservoirs.

To ensure transparency and facilitate access to information, MRN has developed an interactive and accessible online platform, specifically designed to meet GISTM Requirement 15.1. Through this platform, stakeholders can clearly and systematically access up-to-date information on all MRN Tailings Storage Facilities (TSFs), including technical, operational, environmental and social data.

ACCESS: https://gistm.mrn.com.br/en/